Running a small manufacturing business in 2025 isn’t what it used to be.

Margins are tighter. Expectations are higher. And inefficiencies that were once tolerable now feel like deal-breakers.

We’ve seen businesses juggling production, orders, inventory, and finances with a patchwork of spreadsheets and disconnected tools.

It’s exhausting, and it limits growth.

That’s usually the moment they ask: “Is it time for an ERP system?”

If that’s where you’re at, don’t worry.

We’ve worked with many small manufacturing teams, some bootstrapped, others VC-backed, who faced the same issue. And the good news?

The right ERP solution can change the game.

In this blog, we will be explaining the top 5 ERP systems to simplify small-scale manufacturing in 2025. These aren’t just big-name tools.

They’re battle-tested, founder-approved systems that can give your business better control, visibility, and room to grow without overcomplicating your operations.

Whether you’re looking to automate shop floor tasks, manage raw material inventory, or finally ditch those old Excel sheets, this blog is your starting point.

How ERP Systems Help Small Manufacturers Stay Competitive?

In 2025, small-scale manufacturers are facing tougher competition, tighter margins, and rising customer expectations.

Whether you’re managing 10 or 100 orders a day, outdated spreadsheets or disconnected tools are no longer enough.

That’s where ERP systems for small manufacturing businesses become necessary.

Here’s why ERP is a must-have for small manufacturers in 2025:

- Centralized Operations : With a cloud-based ERP system, you get real-time visibility across inventory, production, sales, and finance.

- Improved Production Planning : Tools like MRP (Material Requirements Planning) help forecast demand, manage raw materials, and reduce delays.

- Smarter Inventory Control : Advanced ERP software for small manufacturers offers live inventory tracking, reorder points, and batch control, which are important for avoiding overstock or shortages.

- Cost and Time Savings : Automated workflows reduce manual data entry, labor hours, and costly errors.

- Scalability : Whether you’re a startup or scaling into multiple units, modern cloud ERP for manufacturing adapts as you grow.

- Compliance & Quality Control : With features like lot traceability and digital audits, ERP systems help you meet industry and regulatory standards.

- Customer Satisfaction : Faster response times, accurate delivery dates, and consistent product quality, ERP helps you deliver on your brand promise.

In short, ERP for small-scale manufacturing is about survival and growth.

What Are the Top 5 ERP Solutions Small Businesses Shouldn’t Ignore?

Choosing the right ERP system can be difficult for small manufacturers who are handling daily operations and tight budgets.

That’s why we’ve created a list of the top 5 ERP solutions for small manufacturing businesses in 2025.

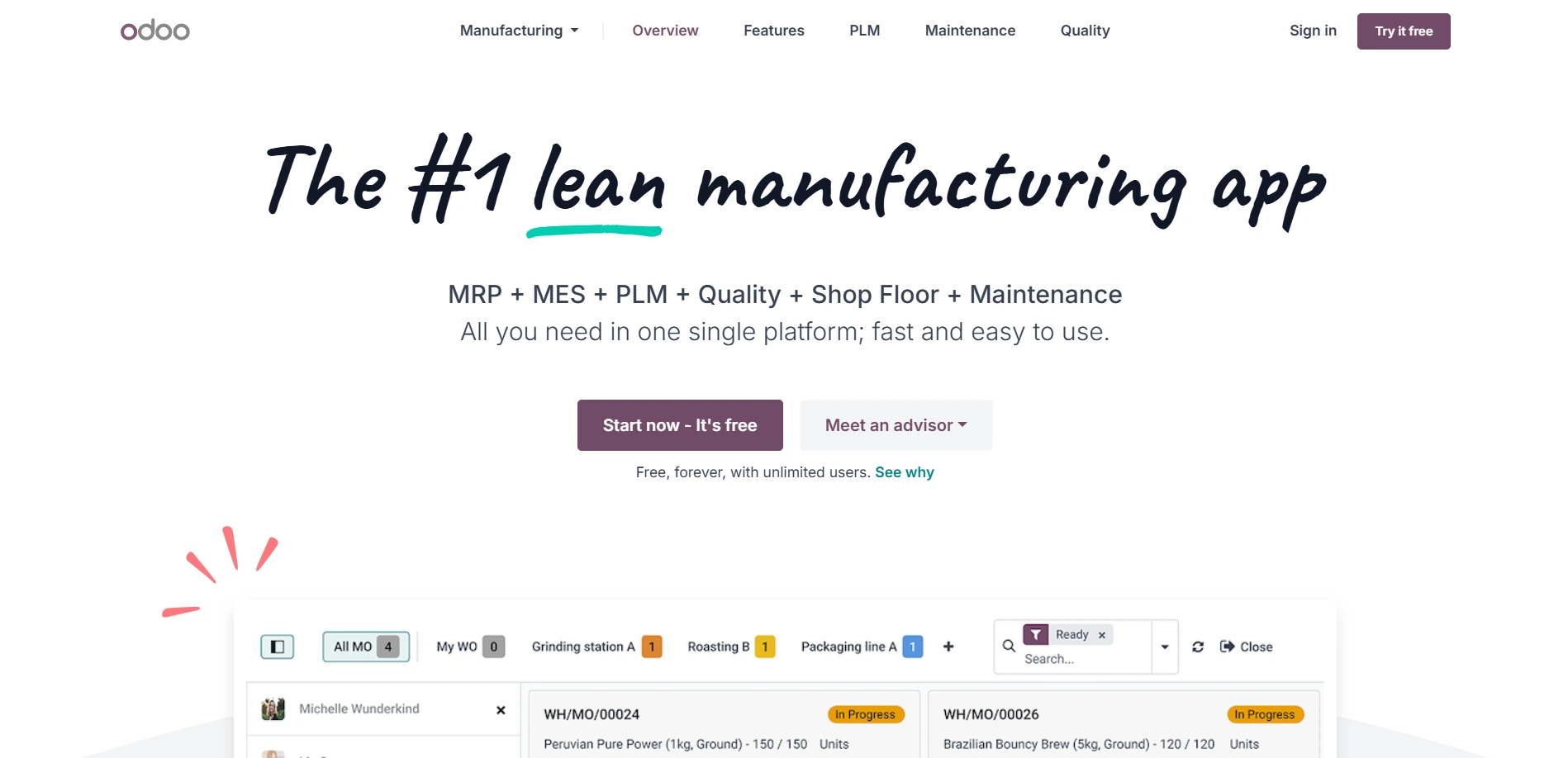

1. Odoo Manufacturing

Why It Stands Out: Odoo offers a powerful, open-source ERP solution for small businesses that is modular, flexible, and easy to scale.

It’s ideal for small-scale manufacturers who need a cost-effective yet complete system.

Key Features:

- Modular apps: Only pay for the features you need.

- Real-time inventory and MRP tracking.

- Work order automation and bill of materials (BoM).

- Barcode scanning and traceability.

- Smooth integration with CRM, sales, HR, and finance modules.

Why It Works for 2025: Odoo ERP for small manufacturers brings enterprise-level tools to growing businesses.

It supports cloud and on-premise deployment and has a strong global community.

Downsides:

- Configuration requires ERP expertise.

- Interfaces can be complex for non-technical teams.

Best For: Startups and mid-sized manufacturers that need a scalable, customizable ERP at an affordable price.

We’ve helped multiple clients deploy Odoo across production, logistics, and finance with great results.

2. Katana MRP

Why It Stands Out: Katana is a cloud-based manufacturing ERP system designed specifically for small businesses.

It’s a favorite for its dynamic interface and real-time shop floor management.

Key Features:

- Live inventory control for raw materials and finished goods.

- Smart auto-booking system for material allocation.

- Real-time production planning and tracking.

- Smooth integration with eCommerce, accounting, and shipping platforms.

Why It Works for 2025: In 2025, agility is key. Katana’s user-friendly dashboard gives production managers full control without requiring ERP expertise.

It helps simplify operations and integrates with tools like QuickBooks, Shopify, and Xero.

Downsides:

- Limited customization

- Not ideal for large-scale or complex manufacturing.

Best For: Product-driven small manufacturing businesses that want a fast, clean, and efficient solution.

It’s perfect for teams that prioritize speed and simplicity.

We’ve worked with clients using Katana to ease D2C production flows and synchronize inventory with Shopify in real-time.

3. NetSuite ERP (Oracle)

Why It Stands Out: As a leading cloud ERP for manufacturing, NetSuite provides a robust, all-in-one solution.

It’s designed for small to medium manufacturers planning to scale.

Key Features:

- Complete manufacturing and inventory management.

- Demand forecasting and supply chain planning.

- Integrated financials, CRM, and HR modules.

- Deep analytics and custom dashboards.

Why It Works for 2025: NetSuite’s advanced features offer unmatched visibility and control.

With its real-time data and customizable workflows, it’s future-ready for fast-growing businesses.

Downsides:

- High initial cost.

- Steep learning curve.

Best For: Ambitious small manufacturing companies looking to scale without switching platforms down the road.

We’ve implemented NetSuite for clients looking to move from fragmented tools to unified platforms.

This ERP for small manufacturing businesses offers best-in-class security, uptime, and multi-user support, key for modern teams.

4. ERPNext

Why It Stands Out: ERPNext is a free, open-source ERP solution for small businesses that offers broad functionality.

It supports small-scale manufacturers with modules for everything from MRP to payroll.

Key Features:

- Manufacturing module with workstations, operations, and routing.

- Real-time inventory and material transfers.

- Integrated CRM, accounting, HR, and project management.

- REST API for easy customization.

Why It Works for 2025: As a community-driven platform, ERPNext evolves fast.

It’s best for tech teams who are looking to experiment, automate, and scale on their terms.

Downsides:

- Lacks hand-holding support for non-technical users.

- Requires hosting and maintenance.

Best For: Manufacturers who want full control over their ERP and have in-house tech skills.

We’ve customized ERPNext for clients in logistics and apparel who wanted control without the price tag.

If you’re comparing ERP systems for small manufacturing, ERPNext is a top contender.

5. JobBoss2

Why It Stands Out: JobBOSS² is built specifically for small, custom job shops.

It’s ideal for make-to-order or mixed-mode manufacturers who need quote-to-cash visibility.

Key Features:

- Custom job scheduling and tracking.

- Integrated quoting, order entry, and invoicing.

- Real-time work-in-progress (WIP) and costing.

- QuickBooks and Xero integration.

Why It Works for 2025: The software simplifies complex workflows with real-time shop floor insights.

With built-in cloud capabilities, it’s perfect for remote visibility.

Downsides:

- Less suited for high-volume or batch manufacturing.

- UI feels slightly dated.

Best For: Job shop manufacturers who require agile scheduling and accurate quoting.

For small manufacturers, this is one of the most affordable ERP for small manufacturers in 2025.

We’ve integrated JobBOSS² for clients in the automotive and metal fabrication industries who needed simplicity and accuracy.

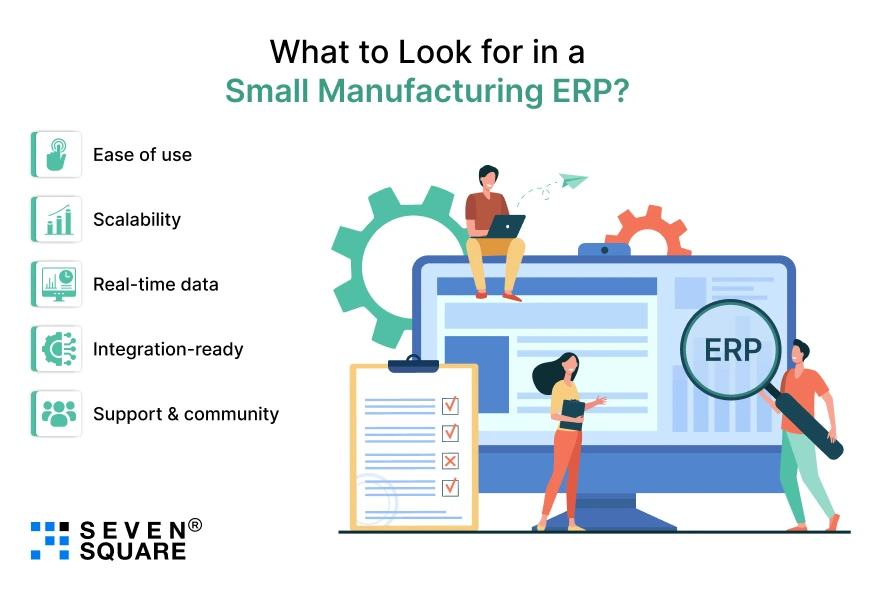

What to Look for in a Small Manufacturing ERP?

When you’re evaluating manufacturing ERP systems 2025, here’s your checklist:

- Ease of use : Can your team handle it easily?

- Scalability : Will it grow with your business?

- Real-time data : Inventory, sales, and production must stay synced.

- Integration-ready : Can it talk to your CRM, eCommerce, or accounting tools?

- Support & community : Especially critical if it’s open-source.

And above all, don’t overpay for features you won’t use.

We’ve helped clients compare ERP systems for small manufacturing to ensure they only pay for what they need.

Why is Seven Square Your Trusted Partner in Manufacturing ERP Implementation?

At Seven Square, we’ve seen how the right ERP solution can change a growing manufacturing business from chaos and guesswork to clarity and control.

But here’s the truth: Most off-the-shelf ERP systems don’t “just work” out of the box, especially for small manufacturing companies with unique workflows, limited staff, and no time to spare.

We build solutions that solve real manufacturing problems.

- Custom ERP Implementation for Small Manufacturing : We customize ERP platforms like Odoo, ERPNext, or Katana for your business.

- Cloud ERP for Manufacturing : Whether you’re on-premise or going cloud-native, we future-proof your stack with clean architecture and easy integrations.

- Clear ROI, Fast Deployment : We don’t drag projects for months. Our team delivers ERP MVPs in weeks, with real business value from Day One.

- Trusted by Founders Across Industries : From electronics to apparel to food processing, we’ve delivered top-notch manufacturing ERP systems.

Trying to Choose the Best ERP System? Contact Us Now!

What’s Next for Small Manufacturers? Smarter ERP Decisions

Always remember, ERP systems for small manufacturing businesses are necessary.

The right cloud ERP for manufacturing can simplify every moving part of your business, from procurement to delivery.

But not every ERP fits every team. If you’re a small manufacturer, your needs are different.

You don’t have the luxury of bloated systems or year-long rollouts. You need something lean, reliable, and customized.

That’s why choosing the right ERP for small-scale manufacturing decisions is a strategic one.

We’ve implemented scalable, budget-smart ERP solutions for manufacturers across industries, from custom job shops to fast-growing D2C factories.

FAQs

- The best ERP software for small manufacturing in 2025 includes tools like Odoo, Katana, ERPNext, and JobBOSS².

- These platforms offer real-time inventory tracking, production planning, and order management for small-scale operations.

- ERP systems help small manufacturers simplify operations by connecting inventory, production, finance, and sales in one place.

- This leads to fewer errors, faster order fulfillment, and better decision-making, all of which are important in today’s competitive market.

- Costs vary based on features, users, and customization.

- On average, small manufacturers can expect to invest between $3,000 to $30,000 for cloud ERP implementation, depending on whether it’s off-the-shelf or custom-built.

- Yes. Cloud ERP for manufacturing allows businesses to scale without heavy infrastructure costs.

- It provides real-time data, smooth updates, and remote collaboration, perfect for growing teams and distributed operations.