Logistics leaders need to understand the harsh truth that buying internal software does not guarantee teams will use it.

Many logistics companies invest heavily in dispatch systems, warehouse tools, fleet dashboards, and tracking platforms. The demos look great. Management is excited.

Reports promise efficiency. But after launch, reality looks very different. Teams quietly return to spreadsheets. Drivers avoid the app.

Warehouse supervisors keep parallel manual logs. Operations managers export data and rebuild reports manually.

This is one of the biggest logistics software usage problems today. You’ll often see issues like:

- Expensive internal tools are used only by 20 to 30% of staff.

- Manual overrides instead of system workflows.

- Excel and WhatsApp are replacing official platforms.

- Duplicate data entry across systems.

- Shadow processes outside the software.

The result? Operational efficiency drops instead of improving.

Instead of faster workflows, teams feel slowed down. Instead of clarity, they experience friction. Instead of automation, they experience extra steps.

This is where AI adoption in logistics changes everything. Modern AI in logistics software focuses on how humans actually work, not just what features exist.

AI-powered systems adapt, suggest, auto-fill, predict, and guide, reducing effort for users. That directly improves adoption behavior.

We’ve worked on logistics software development and AI-enabled internal systems across operations, fleet, and warehouse workflows.

What Is AI in Logistics Software and Why Does It Change User Adoption Behavior?

AI in logistics software means your internal tools are no longer static systems that only record data; they start actively helping users make decisions & complete tasks faster.

Traditional logistics tools are rule-based:

- You enter data.

- You follow fixed steps.

- You generate reports.

- You manually decide your next actions.

AI-powered logistics tools are adaptive:

- They learn from usage patterns.

- They suggest the next steps.

- They auto-complete fields.

- They predict issues.

- They reduce user effort.

That difference is huge for adoption.

AI vs Traditional Logistics Tools

Traditional tools: “Enter all shipment data manually before proceeding.”

AI tools for logistics operations: “Shipment detected from past pattern, confirm details?”

Why Does AI Increase Internal Tool Usage?

AI systems use machine learning in logistics software to understand behavior and reduce friction:

- Smart defaults instead of blank fields.

- Predictive suggestions instead of manual lookup.

- Auto-tagging instead of manual classification.

- Exception alerts instead of dashboard hunting.

- Guided workflows instead of training-heavy steps.

When users feel the system is helping them, adoption rises.

Explore Why Internal Fleet Management Systems Are Failing for Logistics Businesses.

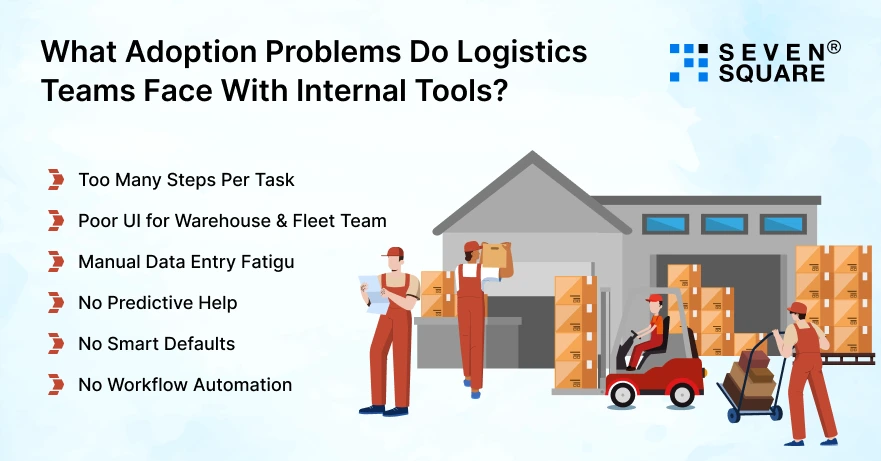

What Adoption Problems Do Logistics Teams Face With Internal Tools?

Adoption problems are rarely about missing features; they are about daily usability. Here are the most common logistics automation challenges affecting adoption today:

- Too Many Steps Per Task: Simple actions like creating a dispatch record or updating delivery status require multiple screens and approvals. Field teams skip them.

- Poor UI for Warehouse & Fleet Teams: Many systems are designed for office users, not drivers, loaders, or floor supervisors. Small buttons, complex forms, and cluttered screens reduce usage.

- Manual Data Entry Fatigue: Drivers and warehouse staff must repeatedly type similar information. Repetition leads to shortcuts and tool avoidance.

- No Predictive Help: Systems record data but don’t guide decisions. Users must think through every step without system support.

- No Smart Defaults: Every field starts empty, even when the system could predict values. This increases task time and frustration.

- No Workflow Automation: Users must trigger each step manually. No auto-routing, no smart task assignment, no intelligent escalation.

What People Are Talking About the Pain Points of Logistics Software Adoption?

Here you can see what people are discussing about the pain points of logistics software adoption by internal teams.

Source: Reddit

What You Can Learn From It?

- Tools exist, but they don’t fit the workflow.

- Field teams still rely on spreadsheets and manual workarounds.

- Documentation and error handling are friction points.

- Device issues and disconnected systems reduce usage.

- Even pilot AI can fail without user readiness and integration.

AI in logistics software reduces friction, predicts user needs, & guides workflows, boosting internal tool adoption.

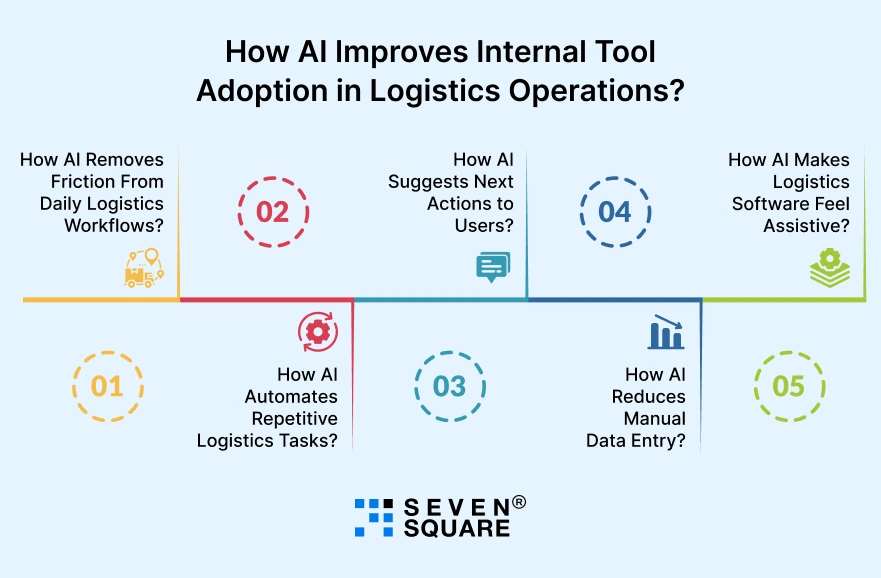

How AI Improves Internal Tool Adoption in Logistics Operations?

Most internal logistics tools fail because they demand too much effort from users. AI flips that model.

Instead of users serving the software, the software starts helping the users. Here’s how AI in logistics software directly improves adoption behavior.

1. How AI Removes Friction From Daily Logistics Workflows?

AI reduces the number of steps required to complete common tasks.

It learns patterns and suggests next actions. Users don’t need to “figure out the system” every time.

Example: Instead of selecting 6 fields manually, AI suggests values based on past dispatch records.

2. How AI Automates Repetitive Logistics Tasks?

Repetitive entries kill adoption. AI auto-fills, auto-tags, and auto-categorizes.

- Shipment type prediction.

- Auto carrier selection.

- Auto delay tagging.

- Smart priority marking.

Less typing = more usage.

3. How AI Suggests Next Actions to Users?

AI-driven internal tools for logistics teams can guide workflows:

- “This delivery may be delayed, notify customer?”

- “Route congestion detected, switch path?”

- “Stock anomaly detected, verify count?”

Guided systems feel supportive.

4. How AI Reduces Manual Data Entry?

AI reads patterns, documents, and history to pre-fill forms. Voice input + AI parsing further reduces effort for drivers and warehouse staff.

5. How AI Makes Logistics Software Feel Assistive?

When tools feel like helpers instead of supervisors, adoption rises naturally. That’s the biggest behavioral shift AI introduces.

Learn to Fix Internal Tools with Logistics Software Development for Maximum Operational Efficiency.

How We Solved Low Internal Tool Adoption for a Logistics Business?

One logistics client approached us with a common problem:

Situation:

- An internal dispatch tool existed.

- Only ~35% active usage.

- Teams maintained Excel backups.

- Drivers avoided mobile apps.

- Reports were unreliable.

What We Implemented Using AI in Logistics Software?

- Predictive field suggestions.

- Auto-carrier selection.

- AI route hints.

- Smart dispatch templates.

- Exception alerts instead of manual checks.

Results After Rollout:

- Tool adoption increased to 82%.

- Manual entries reduced by ~40%.

- Dispatch time reduced significantly.

- Spreadsheet dependency nearly removed.

Want to Implement AI in Your Logistics Solution? Contact Us Today!

How Do We Design AI-Enabled Logistics Software That Teams Use?

Our logistics software approach is adoption-first, not feature-first. We design AI-enabled internal systems that match real operational behavior. We focus on:

- AI-first UX design.

- Workflow intelligence mapping.

- Role-based AI suggestions.

- Smart defaults everywhere possible.

- Friction audit before development.

- Adoption analytics tracking.

- AI workflow automation layers.

- Field-team usability testing.

- Low-training interface design.

We build logistics tools people actually use.

How to Get Started With AI-Powered Logistics Internal Tools?

If your logistics internal tools are underused, slow, or bypassed, the problem may not be your platform. It may be missing an intelligence layer.

AI doesn’t just automate logistics operations. It improves how humans interact with logistics systems. That’s the real adoption driver.

We’ve helped logistics teams transform low-usage internal platforms into AI-assisted operational tools with measurable adoption gains.

If you’re planning to improve AI in logistics software adoption, we can audit your current system, identify friction points, and design an AI adoption roadmap.

FAQs

- AI in logistics software uses predictive models and automation to help users complete tasks faster and make better operational decisions.

- AI reduces friction, auto-fills data, suggests next steps, and simplifies workflows, making tools easier and faster to use.

- Predictive entry, smart defaults, AI alerts, workflow suggestions, and voice input features increase usage significantly.

- Yes. AI reduces manual entries, flags anomalies, and guides workflows, which increases warehouse team usage.