In a traditional warehouse, you’ll see workers manually picking items from shelves, clipboards filled with stock counts, and supervisors trying to catch errors before they hit delivery trucks.

It works until demand increases, orders multiply, and mistakes happen. Manual processes often lead to delays, misplaced inventory, and rising operational costs.

Imagine a modern warehouse. Autonomous go through aisles, sensors update stock levels in real time, & smart dashboards show managers exactly where every product is.

Instead of chaos, there’s speed, precision, and cost savings. This is the power of warehouse automation solutions.

At Seven Square, we’ve seen how companies of all sizes benefit from moving away from outdated methods.

By using warehouse automation software, robotics, and AI systems, businesses achieve smart inventory management, where human effort is reserved for strategy.

In this blog, you’ll know exactly which type of automation fits your warehouse needs and why you should go for Warehouse Automation Solutions.

What Is Warehouse Automation? (And Why It’s No Longer Optional?)

Warehouse automation means using technology, software, and robotics to make warehouse operations faster, more accurate, and less dependent on manual labor.

Instead of people walking miles each day to pick orders or updating spreadsheets to track stock, automation handles these tasks with minimal human input.

There are two main sides of warehouse automation:

- Software-based automation: Tools like Warehouse Management Systems (WMS), AI forecasting, and IoT sensors that track inventory in real-time. Imagine a system automatically alerting you when stock is low or rerouting workers to avoid congestion on the floor.

- Robotics-based automation: Physical solutions such as autonomous mobile robots (AMRs), conveyors, or automated storage and retrieval systems (AS/RS). These machines physically move goods, reducing human errors and increasing throughput.

At Seven Square, we believe warehouse automation is the backbone of competitive supply chains.

Without it, businesses risk slower fulfillment, higher costs, and unhappy customers.

Learn more about Fleet Management Software Features.

What Are the Key Warehouse Automation Solutions For Smart Inventory Management?

Here you can see some of the key automated warehouse solutions that you should utilize for your business.

1. Automated Storage and Retrieval Systems (AS/RS)

- An automated storage & retrieval system replaces forklifts & manual picking with cranes, shuttles, or carousels that store & retrieve items automatically.

- The result? Better space utilization, faster access, and fewer errors.

- While AS/RS pricing can feel like a big investment, the long-term savings in labor and storage optimization quickly outweigh upfront costs.

2. Goods-to-Person Picking Systems

- Instead of workers traveling across aisles to find products, a goods-to-person system brings items directly to the operator.

- Compared to conveyors or fully manual picking, this reduces walking time, improves accuracy, and speeds up order fulfillment automation.

- Yes, the system cost vs conveyor may be higher, but it delivers faster ROI by reducing labor fatigue and picking mistakes.

3. Autonomous Mobile Robots (AMRs)

- Autonomous mobile robots for warehouses move independently, carrying bins, pallets, or products to workstations.

- For small and mid-sized warehouses, they’re a cost-friendly alternative to large fixed systems.

- Many of our clients at Seven Square find the AMR robots for warehouse cost justifiable when balanced against labor shortages, scalability, & efficiency gains.

4. Pick-to-Light & Put-to-Light Systems

- Fast-moving SKUs demand fast-moving solutions.

- Pick-to-light and put-to-light systems use LED lights to guide workers to the right items and locations.

- This improves accuracy and speed while reducing training time.

- As part of broader robotics in inventory management, they are especially effective in eCommerce warehouses with high order volumes.

5. WMS + IoT Integration with Automation

- The smartest warehouses don’t just move goods; they provide visibility.

- By combining a WMS integration with automation and IoT sensors for warehouses, managers get real-time data on stock levels, equipment health, and order progress.

- This makes inventory more predictable, reduces stockouts, and drives better decision-making.

- At Seven Square, we help businesses integrate these tools so every item is tracked from inbound to outbound smoothly.

Explore when you need a Manufacturing Management System for your business.

What Are the Industry-Specific Warehouse Automation Solutions?

At Seven Square, we know that one size doesn’t fit all. Every industry has unique challenges, which is why warehouse automation solutions must be personalized.

1. eCommerce Fulfillment Automation

- In eCommerce, speed is everything.

- Warehouse automation for ecommerce fulfillment allows lightning-fast picking, packing, and shipping.

- Tools like goods-to-person systems and AMRs cut delivery times and reduce errors, ensuring customers get the right product on time.

2. 3PL Automation

- For third-party logistics providers, the biggest challenge is handling multiple clients under one roof.

- 3PL warehouse automation solutions give visibility across accounts, manage diverse SKUs, and prevent mix-ups.

- With automation, 3PLs scale quickly without adding headcount.

3. Cold Storage Warehouse Automation

- Energy costs can eat into profits.

- Cold storage warehouse automation solutions reduce manual handling, optimize space, and minimize door openings to maintain temperature.

- Automation keeps goods fresh while lowering energy bills.

4. SMB Automation Solutions

- Automation isn’t just for large enterprises.

- Small warehouse automation solutions like mobile robots and smart WMS integrations help growing businesses scale affordably.

- At Seven Square, we design solutions that let SMBs compete with bigger players without massive upfront investments.

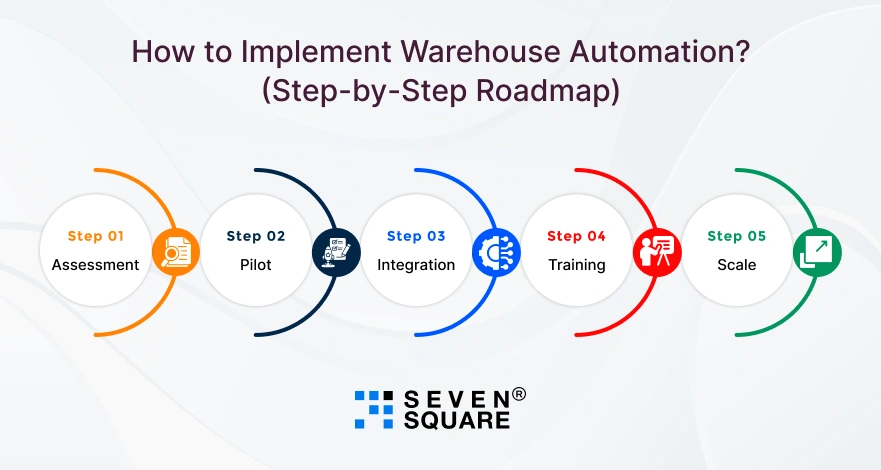

How to Implement Warehouse Automation? (Step-by-Step Roadmap)

At Seven Square, we believe successful warehouse automation isn’t a risky leap; it’s a structured journey.

Businesses that follow a clear roadmap see higher ROI, faster adoption, and smoother operations.

Here’s how we guide our clients through automation:

1. Assessment

- We begin by analyzing existing workflows, costs, and bottlenecks.

- This step identifies where warehouse automation solutions will deliver the most impact to improve space utilization & improve smart inventory management.

2. Pilot

- Next, we launch a pilot project.

- This could be testing autonomous mobile robots (AMRs) in one zone or adding a WMS integration with automation for order tracking.

- A pilot proves value quickly while minimizing risk.

3. Integration

- Once the pilot succeeds, we will integrate automation with your existing ERP, WMS, and automation integration services.

- This is where IoT sensors, robotics, and data analytics start working together as one warehouse automation system.

4. Training

- Technology is only as strong as the team using it.

- We ensure your workforce is trained to operate smoothly alongside robotics, warehouse automation software, and AI systems.

5. Scale

- Finally, we expand automation across the warehouse, whether that means rolling out AMRs, deploying AS/RS, or adding pick-to-light systems.

- Scaling happens once ROI is visible and proven.

The average warehouse automation implementation timeline ranges from 2 to 3 months, depending on complexity and scope.

Want a Custom Warehouse Automation System? Contact Us Now!

What is the Future of Warehouse Automation? AI, Robotics, and Beyond

Tomorrow’s warehouses will look very different from today’s. At Seven Square, we’re already preparing clients for the future of warehouse automation:

- AI-based demand forecasting to predict stock needs.

- Robotic swarms of smaller bots working collaboratively.

- Digital twins for real-time warehouse simulations and planning.

The future belongs to businesses that combine robotics, AI, and IoT into a unified system for smart inventory management.

FAQs

- Warehouse automation solutions use robotics, AI, and warehouse automation software to simplify inventory management, order picking, & fulfillment.

- They reduce manual errors, improve speed, and cut operational costs.

- Yes, small warehouse automation solutions like AMRs, pick-to-light systems, and cloud-based WMS are affordable entry points.

- Many SMBs achieve ROI in less than a year by reducing labor costs and improving order accuracy.

- The future of warehouse automation includes AI-based demand forecasting, robotic swarms, and digital twins for simulation.

- Businesses that follow these innovations achieve smart inventory management and long-term competitiveness.

- Robotics like AMRs, conveyors, and goods-to-person systems boost order fulfillment automation to reduce travel time, increase picking speed, and ensure accuracy.