Delayed dispatches. Manual Excel sheets. ERP and TMS are not syncing.

Warehouse staff are avoiding the system and using WhatsApp instead. If this sounds familiar, you’re not alone.

Many companies invest heavily in logistics software development, yet operational efficiency does not improve. In fact, sometimes it gets worse.

Teams spend more time fixing system errors than moving goods. Here’s the harsh truth:

If your warehouse still depends on WhatsApp & spreadsheets despite investing in software, your logistics software development strategy was never aligned with operations.

They buy or build tools, integrate a few dashboards, and expect automation to solve everything. But real logistics automation is not about installing software.

It is about aligning technology with real warehouse and transport workflows.

According to multiple industry reports, supply chain inefficiencies cost companies billions every year due to poor system integration & manual processes.

We’ve audited multiple failing logistics internal tools. And we keep seeing the same pattern:

- Software built without understanding ground-level operations.

- Systems designed for managers, not warehouse staff.

- Tools that look powerful but don’t solve real problems.

In this blog, you will learn about logistics software development and why you should think about having logistics internal tools for your business.

Why Do Logistics Internal Tools Fail to Improve Operational Efficiency?

Wondering “Why is our new system not improving performance?”. Here are the real reasons:

1. Why Custom Logistics Tools Hurt Operational Efficiency?

Custom software sounds like the perfect solution. But when built incorrectly, it creates more problems than it solves.

- No Operational Workflow Mapping: You must map dispatch flow, inventory movement, approval layers, & exception handling. Without this, logistics software development becomes guesswork.

- Poor UX for Warehouse Workers: Warehouse teams need speed, clarity, & mobile-friendly screens. If updating inventory takes 10 clicks, they will bypass the system.

- Over-Engineered Dashboards: Executives love analytics. But if the backend operations are broken, dashboards only show delayed data.

When companies skip operational alignment, custom tools quietly reduce productivity instead of improving it.

2. Why Integration with ERP, WMS & TMS Breaks Down?

Integration is where most logistics internal tools fail. A company may use:

- An ERP system for finance.

- A warehouse management software (WMS) for inventory.

- A transport management system (TMS) for dispatch.

- A separate fleet tracking tool.

But if these systems don’t communicate in real time, operational efficiency collapses.

Properly integrating logistics tools with ERP requires structured architecture planning during logistics software development.

3. Why Employees Don’t Use Internal Logistics Software?

Even the best system fails if people don’t use it. Here’s why internal logistics software often gets ignored:

- No Proper Training: Teams are expected to “figure it out.” Without hands-on onboarding, resistance grows.

- Complex User Interface: If drivers or warehouse operators struggle to update data quickly, they revert to manual communication.

- No Mobile Optimization: Logistics happens on the move. If your system is desktop-only, field teams will avoid it.

So, how to build internal logistics tools that employees will use?

- Keep interfaces simple.

- Prioritize mobile-first design.

- Reduce clicks and data entry.

- Align screens with actual workflows.

- Involve operations teams during development.

Technology adoption is not about forcing compliance. It is about designing tools that make work easier.

Explore Why AI Chatbots for Mobile Apps Helps to Improve Customer Retention.

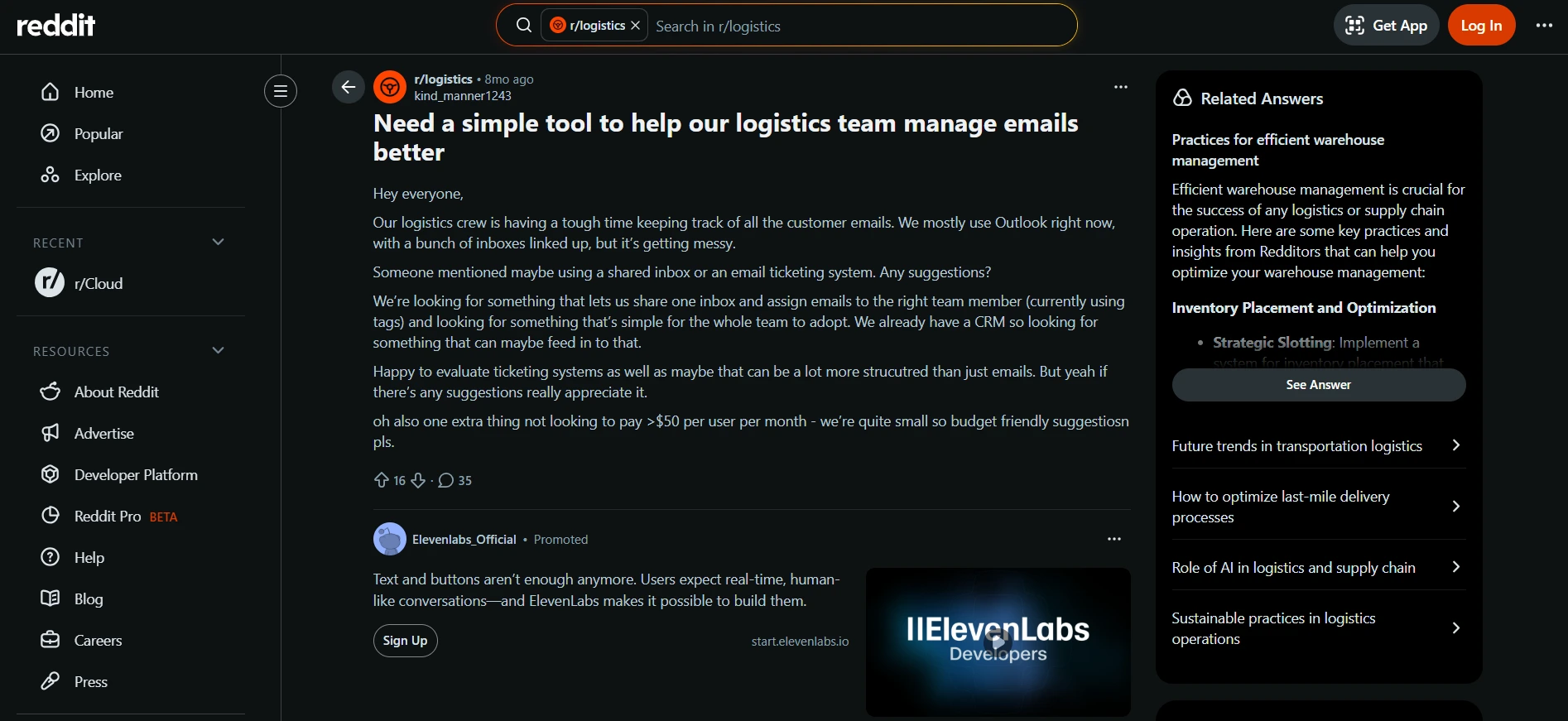

What People From Real Logistics Businesses Are Saying?

Here you can say one of the clearest ways to understand why logistics internal tools and logistics software development often fail to improve operational efficiency.

Source: Reddit

What Are the Common Pain Points that Logistics Internal Tools Fail to Address?

- Software is too complex or expensive for true day-to-day use.

- Critical operational data (e.g., pallet movements, inventory) isn’t tracked in real time.

- ERP or bundled systems promise features but deliver a poor user experience.

- Core tasks like documentation still cause manual work and inefficiency.

- Users openly express frustration and tool avoidance.

These real problems show what so many companies face after investing in logistics software development: Tools that were designed without operational reality in mind.

Why Do Most Logistics Software Development Companies Build the Wrong Solution?

Most vendors fail because they don’t understand logistics operations. Here’s what usually goes wrong in logistics software development:

1. They Build Features, Not Workflows

A dispatch manager doesn’t care about fancy dashboards. They care about faster truck allocation.

A warehouse supervisor doesn’t need 30 reports. They need real-time inventory visibility.

When software is built around features instead of workflows, operational efficiency suffers.

2. No Ground-Level Operations Audit

Before development begins, companies must map:

- Order processing flow.

- Warehouse picking process.

- Delivery dispatch cycles.

- Exception handling scenarios.

Without this, software becomes a guesswork project.

3. No KPI Alignment

Most systems don’t track:

- Dispatch turnaround time.

- Inventory accuracy rate.

- Manual intervention reduction.

- On-time delivery percentage.

Without clear metrics, you cannot measure logistics software ROI.

4. No Scalability Planning

Many logistics software solutions work fine at 100 orders per day.

They fail at 5,000 orders per day.

Scalable architecture is important.

Explore How Logistics App Development Can Reduce Operational Costs.

How We Solved a Failing Logistics Internal Tool?

A mid-sized distribution company approached Seven Square because:

- Their warehouse management software (WMS) didn’t sync with ERP.

- Their transport management system (TMS) required manual updates.

- Dispatch teams were using Excel to track shipments.

- Reports were delayed by 24 hours.

Despite investing heavily in internal tools, operational efficiency had not improved.

After auditing their system, we identified:

- No real-time API integration.

- No automation between WMS and TMS.

- Manual reconciliation processes.

- Poor mobile usability.

Their logistics software development approach had focused on dashboards instead of data flow.

The Results:

- 32% faster dispatch cycles.

- 45% reduction in manual data entry.

- 98% inventory accuracy.

- Real-time shipment tracking.

This is what strategic supply chain software development looks like when built correctly.

Want Custom Logistics Development Services? Contact Us Today!

How to Build Logistics Software That Improves Operational Efficiency?

If you want your logistics software development to succeed, follow this framework:

1. Integrate Logistics Tools with ERP Properly

Poor integration is the biggest failure point. When integrating logistics tools with ERP:

- Use real-time APIs.

- Avoid batch data sync.

- Eliminate duplicate data entry.

- Build unified dashboards.

Proper integration between ERP, WMS, and TMS creates real operational efficiency.

2. Build Tools Employees Actually Want to Use

If you’re wondering how to build internal logistics tools that employees will use:

- Keep the interface simple.

- Optimize for mobile.

- Reduce manual typing.

- Involve warehouse staff in testing.

Adoption drives efficiency.

3. Focus on Automation

Automation examples:

- Auto-assign nearest driver.

- Auto-generate shipping documents.

- Auto-update inventory after dispatch.

- Auto-alert for delays.

That’s real logistics automation.

What Happens If You Don’t Fix Your Logistics Internal Tools?

If your systems remain inefficient:

- Your competitor reduces delivery time.

- Your operational cost increases.

- Your customer complaints rise.

- Your team burns out.

Meanwhile, companies investing in proper logistics software development gain:

- Faster last-mile delivery.

- Lower overhead costs.

- Better inventory control.

- Higher customer retention.

Operational efficiency is now a competitive advantage. If you delay fixing internal tools, someone else won’t.

How Can We Help You Improve Operational Efficiency?

Your system needs a structural redesign. We offer:

- Logistics software audit.

- Performance gap analysis.

- Custom development roadmap.

- Integration restructuring.

- Automation strategy.

We’ve solved these problems before.

And if you don’t improve your internal logistics tools now, your competitors will, and they’ll move faster than you.

FAQs

- Most logistics internal tools fail because they are built without understanding operational workflows.

- Poor ERP integration, lack of automation, and low employee adoption reduce efficiency instead of improving it.

- Logistics software development involves designing & building systems like warehouse management software, transport management systems.

- Automation tools that improve inventory tracking, dispatch, and delivery efficiency.

- Logistics automation reduces manual data entry, eliminates delays, improves real-time tracking, and streamlines dispatch operations.

- It increases speed, accuracy, and overall supply chain performance.

- Integration requires API-based architecture, real-time data syncing, and unified dashboards.

- Proper planning during logistics software development prevents data silos and system mismatches.