Logistics companies are spending heavily on fleet management software & internal tools. Everything looks modern: Dashboards, GPS tracking, reports, alerts, and analytics.

But operations teams are still struggling every single day. Deliveries are delayed. Fuel costs are rising. Vehicles sit idle. Compliance risks keep appearing.

Drivers bypass systems. Managers don’t trust the reports. Sound familiar?

This is the real truth behind many internal fleet management systems challenges. Companies install software, but operational efficiency doesn’t improve.

Many logistics teams we speak with say the same thing: We have logistics fleet software, but we still run operations on calls, WhatsApp, and spreadsheets.

Legacy and manual fleet management systems were never designed for real-time logistics scale. They were built for record-keeping, not operational intelligence.

As fleet size grows, routes get complex, and compliance rules tighten, these systems start breaking silently.

Because we’ve worked directly on building and fixing fleet management software platforms for logistics companies.

We’ve seen failed deployments, unused dashboards, and expensive systems that operations teams completely ignore. This blog is based on practical experience.

Why Do Most Fleet Management Software Implementations Fail in Logistics Companies?

Most fleet management software failures are implementation and design failures. Companies buy software expecting transformation.

They deploy it like an IT upgrade, not an operations system. That is the root of most fleet management system shortcomings.

Here are the most common causes of fleet management software failure we repeatedly see:

1. No Real-Time Fleet Tracking Software Integration

Tracking exists, but it’s not connected to:

- Dispatch decisions.

- Delay alerts.

- Route correction.

- Exception handling.

Tracking without operational triggers becomes passive data.

2. Poor Driver Behavior Analytics

Many systems collect driver data but don’t convert it into:

- Coaching workflows.

- Risk scoring.

- Safety alerts.

- Incentive programs.

Without action, analytics is just storage.

3. No Predictive Maintenance for Fleets

Maintenance is still calendar-based instead of data-based. Good systems should predict failures using:

- Engine data.

- Usage patterns.

- Fault codes.

- Wear indicators.

Without predictive maintenance, breakdowns remain “surprises.”

4. No Route Optimization Software for Logistics

Routes are planned once and never adjusted using:

- Traffic.

- Fuel efficiency.

- Delivery priority.

- Vehicle load.

- Driver behavior.

Static routing leads to rising costs.

5. No Adoption by Ground Staff

This is the biggest silent killer of fleet software deployment mistakes: If drivers and supervisors don’t use the system daily, the system is already dead.

Reasons:

- Too complex.

- Too slow.

- Too many fields.

- No mobile usability.

- No training.

- No operational benefit felt by users.

Software unused = software failed.

Learn Why Internal Logistics Tools Fails to Improve Operational Efficiency.

What Hidden Operational Gaps Kill Fleet Efficiency (But Dashboards Don’t Show)?

Modern dashboards look impressive. Charts, maps, KPIs, graphs, everything appears under control.

Many vehicle tracking & logistics software problems hide behind these visuals. These are the silent gaps that damage performance even when the dashboard says “all good.”

1. Alerts Without Automation

Many GPS fleet tracking software gaps include alerts that only notify but don’t act.

Example:

- The overspeed alert comes.

- No auto-driver warning.

- No score impact.

- No compliance log.

- No penalty workflow.

Alerts must connect to consequences.

2. Tracking Without Accountability

Tracking shows vehicle movement, but:

- No driver ownership.

- No exception reason capture.

- No audit trail.

- No supervisor validation.

Without accountability, behavior doesn’t change.

3. Fleet Fuel Management Software Issues

Fuel modules often fail because:

- Manual entries are allowed.

- No anomaly detection.

- No consumption benchmarks.

- No route vs fuel correlation.

Fuel tracking without intelligence invites leakage.

4. Reports Without Decision Triggers

Reports get generated weekly or monthly. But there are no built-in decision triggers like:

- Auto vendor scheduling.

- Route re-assignment.

- Driver retraining.

- Vehicle retirement flags.

Reports should drive decisions, not just documentation.

Learn How AI Recommendation Engine Can Increase App Retention Rates.

What Are the Real Fleet Management System Pain Points for Logistics Businesses?

These are the real problems with internal fleet management systems and fleet tracking failures, as seen by looking at what logistics and fleet operators themselves are saying online.

Source: Reddit

What Does It Show?

- Many systems fail to deliver reliable real-time tracking.

- Basic functionality like maintenance scheduling, fuel tracking, and simple workflows are missing or hard to use.

- Legacy tools like spreadsheets still dominate because fleet software doesn’t fit real work.

- Logistics professionals actively ask for better tools, a clear signal of unmet demand.

It shows that internal fleet management systems fail not because the idea is wrong, but because the execution and operational alignment are wrong.

Why Off-the-Shelf Fleet Management Software Still Fails Without Custom Logistics Workflows?

Many logistics companies buy ready-made fleet management software expecting instant improvement. The demo looks perfect. Features look complete.

But after deployment, teams realize something important: Generic software does not match real logistics workflows.

This is where most logistics fleet software failures begin. Off-the-shelf tools are built for “average” use cases. But logistics operations are never average. Every fleet has:

- Different dispatch rules.

- Different compliance needs.

- Different fuel approval flows.

- Different maintenance processes.

- Different exception handling steps.

Common problems with ready-made fleet systems:

- No custom approval workflows.

- No exception-based alerts.

- Weak integration with ERP / warehouse / billing.

- No role-based operational dashboards.

- No rule engine for fleet policies.

Result:Teams go back to calls, chats, and spreadsheets, even after buying software.

Explore the Best AI User Engagement Techniques.

How We Solved a Fleet Management Software Failure?

A logistics company came to us after a failed fleet management system rollout.

What was the Issue?

- No decision workflows are connected to alerts.

- No predictive maintenance logic.

- No driver scorecards.

- No route optimization software for logistics.

- No adoption training for ground staff.

What we changed?

- Added rule-based alert actions.

- Built driver behavior analytics scoring.

- Connected fuel anomalies to approval workflows.

- Added predictive maintenance triggers.

- Created role-based dashboards.

- Simplified driver mobile UX.

This is why custom fleet management software design beats feature-heavy generic tools.

Do You Want Custom Fleet Management Software? Contact Us Today!

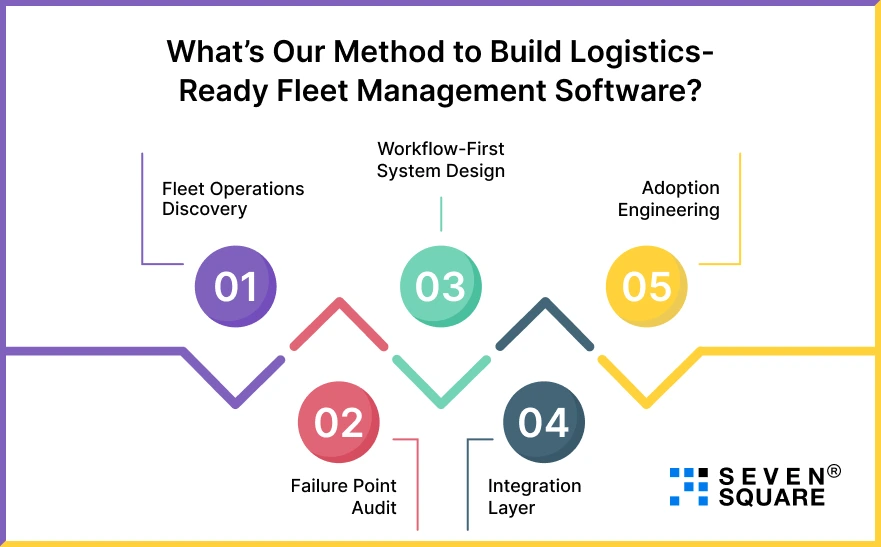

What’s Our Method to Build Logistics-Ready Fleet Management Software?

We don’t start with features. We start with fleet failures and operational gaps. Our fleet management software development approach:

Step 1: Fleet Operations Discovery

We study:

- Dispatch flow.

- Fuel flow.

- Maintenance flow.

- Compliance flow.

Step 2: Failure Point Audit

We identify:

- Fleet tracking failures.

- System adoption gaps.

- Reporting blind spots.

- Workflow breaks.

Step 3: Workflow-First System Design

We design:

- Action workflows.

- Approval chains.

- Exception handling.

- Automated triggers.

Step 4: Integration Layer

We connect with:

- ERP.

- Warehouse systems.

- Billing.

- Compliance tools.

- IoT devices.

Step 5: Adoption Engineering

Because unused software = failed software:

- Driver-first mobile UX.

- Supervisor dashboards.

- Training flows.

- Rollout support.

How Can Logistics Companies Choose the Right Fleet Management Software Partner?

Choosing the right fleet management software partner matters more than choosing software features. Use this checklist:

- Industry Understanding: Do they understand logistics operations, not just software?

- Custom Workflow Capability: Can they build around your real fleet processes?

- Integration Strength: Can they connect tracking, fuel, maintenance, ERP, and billing?

- Predictive + Analytics Capability: Do they go beyond tracking into prediction?

- Adoption Support: Do they help with rollout and training?

- Proof of Similar Projects: Do they have real logistics or fleet case experience?

How Can We Help You Fix Your Fleet Management Software Before It Fails Again?

If your fleet management software exists, but results don’t, the problem is not your fleet size. It’s your system design. We help logistics companies:

- Audit failing fleet systems.

- Identify operational gaps.

- Redesign workflows.

- Build custom logistics fleet software.

- Integrate tracking, fuel, and maintenance intelligence.

- Improve real-world adoption.

FAQs

- Because it’s deployed as a tool, not an operations system, and lacks workflow integration and staff adoption.

- Passive tracking, no action triggers, unreliable devices, and no accountability workflows.

- By redesigning workflows, adding predictive analytics, integrating systems, and improving field adoption.

- For growing logistics companies, yes. Custom systems match real workflows and scale better.

- Real-time tracking, predictive maintenance, fuel intelligence, route optimization, and decision dashboards.