Most warehouse leaders don’t notice system cracks when operations are small. Everything looks fine at 2,000 orders a day. Reports load. Inventory looks accurate.

Dispatch runs on time. Then the scale happens. Order volume doubles. New sales channels are added. Another warehouse goes live. Peak season hits.

Suddenly, the warehouse management system that once felt stable starts behaving unpredictably.

We have seen this for many growing logistics companies as their warehouse management system was built for today, not for scale.

We work deeply in logistics software development and internal tools.

We are often called when companies face serious warehouse management system failures, slow systems, broken integrations, wrong stock numbers, & delayed shipments.

- Sudden Order Spikes → System Slowdown: When order volume increases, poorly optimized WMS databases can’t keep up. This is one of the earliest signs your warehouse management system isn’t scalable.

- Inventory Mismatch → Customer Complaints: At scale, small sync delays become big accuracy gaps. These are classic warehouse software problems at scale.

- Peak Season → WMS Crashes: Systems that worked all year suddenly crash under load. This exposes deep WMS scalability issues, especially where no load testing was done.

This is where many warehouse management system failures become visible to leadership.

Explore Why Internal Fleet Management Systems Are Failing for Logistics Businesses.

Why Do Warehouse Management Systems Fail at Scale in Real Companies?

Here are the most common technical and implementation-level reasons that cause warehouse management systems to fail in real companies.

1. What Happens When WMS Architecture Is Not Built for Growth?

Many systems start as simple internal tools and grow without redesign. That creates structural risk.

- Monolithic WMS design: Picking, packing, inventory, and reporting all share the same runtime and database load. One heavy process slows everything.

- No load distribution: There is no separation between read & write workloads. Reports compete with live operations. Dashboards slow down transactions.

- Synchronous processing bottlenecks: Every action waits for the previous one to finish. At high volume, queues grow & users experience lag.

These are hidden WMS performance limitations that only appear under scale.

2. Why WMS Integration Problems Break Operations?

Integration works fine at low volume, then breaks under pressure.

WMS integration with ERP challenges

- Slow bidirectional sync.

- Retry storms.

- Duplicate records.

API rate limits: External systems restrict request frequency. At scale, limits are hit quickly, causing sync gaps.

Middleware failures: If message brokers or connectors are weak, one failure blocks multiple downstream updates.

These integration weak points are major WMS deployment challenges and a top reason enterprise rollouts struggle.

3. What Performance Limitations Appear at High Order Volumes?

Some limits are not visible until transaction counts grow.

- Batch jobs delay real-time data: Nightly or hourly batch updates cannot keep up with real-time operations anymore.

- Inventory locking conflicts: Multiple users and bots update the same SKUs. Record locks create delays and mismatches.

- Queue backlogs: Event queues grow faster than they are processed. Status updates arrive late. Teams work with outdated data.

These patterns directly lead to warehouse software problems at scale.

4. Why Warehouse System Implementation Pitfalls Show Later?

Many failures are seeded during early implementation but only show up months later.

- Shortcut deployments: Teams skip workflow mapping and edge-case handling to go live faster.

- Copied workflows: Processes are copied from another warehouse without matching real ground operations.

- No scale testing: Systems are tested with 1,000 orders, but production runs at 50,000. No stress simulation is done.

This causes warehouse management systems to fail when growth arrives.

Learn How AI Recommendation Engine Can Increase App Retention Rates.

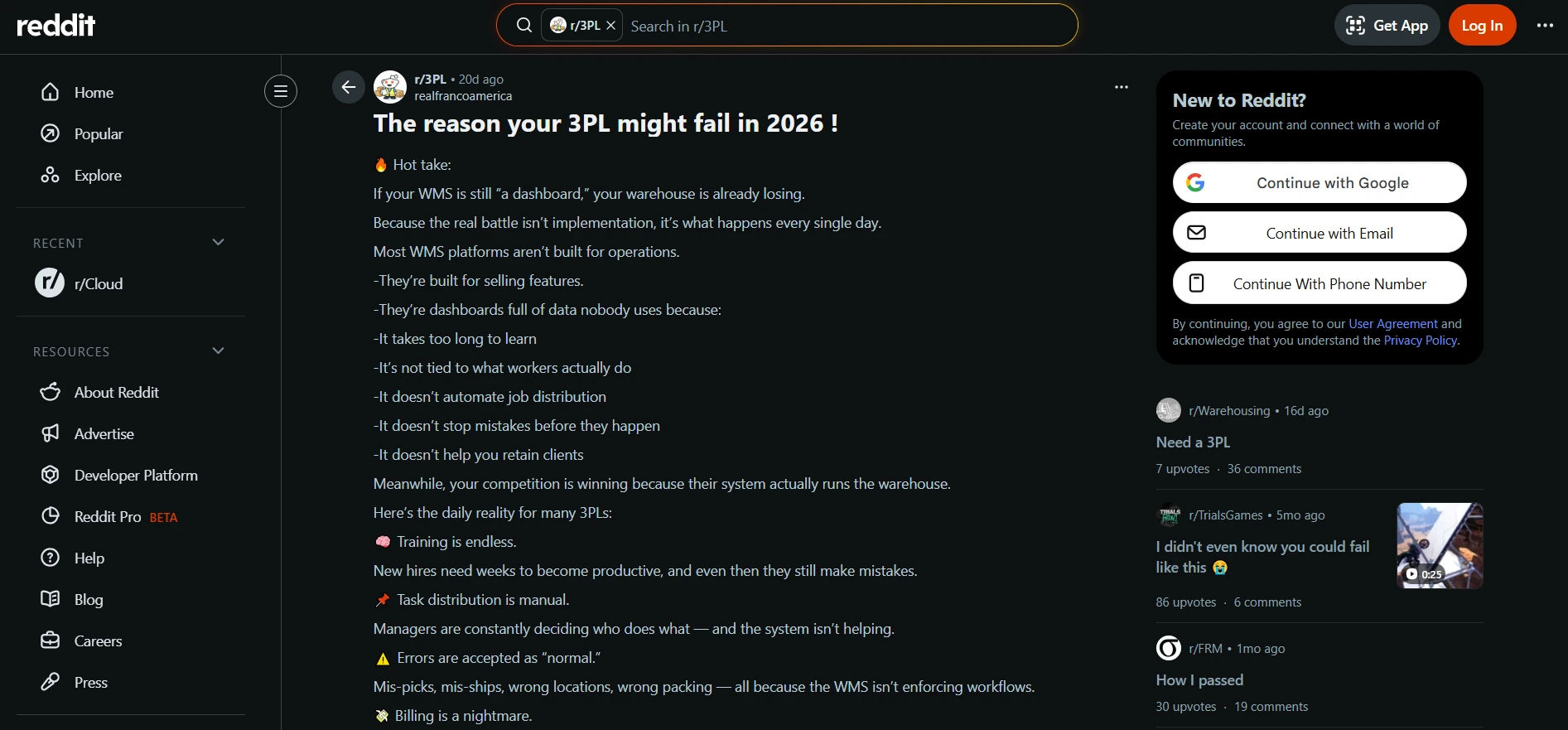

What Are the Real Warehouse Management System Failures People Are Talking About?

When it comes to warehouse management system failures and operational pain, the industry’s frustrations are shared by many people.

Source: Reddit

What Does It Mean?

- Warehouse software that looks fine on paper fails under real operational stress.

- Usability problems create hidden friction in everyday tasks.

- Inventory errors and integration lags become expensive at scale.

- ERP-based WMS modules often aren’t strong enough for complex fulfillment.

- Small mistakes become large operational breakdowns without real-time enforcement.

These are exactly the kinds of issues high-growth logistics businesses face when signs that your warehouse management system can’t keep up start showing up across teams.

What Most Warehouse Management Software Gets Wrong About Multi-Warehouse Scale?

Many teams assume that if a warehouse management system works in one warehouse, it will work the same way across five.

That causes serious WMS scalability issues. Most warehouse software is designed around a single-site logic model.

When you expand to multiple warehouses, hidden limits appear.

- No real multi-location data model: Stock, bins, & movements are tied to one facility design. Cross-warehouse transfers become hacks instead of native flows.

- No event-based architecture: Systems rely on periodic updates instead of real-time events. This causes sync lag between sites.

- Shared database overload: All warehouses hit the same tables and transactions. At a large scale, this creates contention and slowdown.

- Static slotting and routing logic: Routing rules don’t adapt to different warehouse layouts, zones, or throughput levels.

Growing companies see more warehouse software problems at scale instead of more efficiency.

Learn to Fix Internal Tools with Logistics Software Development for Maximum Operational Efficiency.

How We Diagnosed and Fixed a Failing Warehouse Management System?

We’re often called when a warehouse management system is already failing, not when it’s comfortable. One recurring rescue pattern looks like this:

What Was Breaking?

- Order processing is delayed during peak hours.

- Inventory mismatch across two warehouses.

- ERP sync is taking 20 to 40 minutes.

- Pick lists are generating slowly.

- Users are refreshing screens repeatedly.

These are classic signs your warehouse management system can’t keep up.

How We Re-Architected It?

We typically fix this through:

- Async event queues for inventory updates.

- Service separation (orders / inventory / reporting).

- Read replicas for dashboards.

- API retry + throttling control.

- Warehouse-wise data partitioning.

What Improved After the Fix?

- Faster order throughput.

- Near real-time inventory sync.

- Stable peak load handling.

- Zero crashes during sale spikes.

This is how warehouse management system failures are prevented by fixing the architecture.

Want an Internal System for Warehouse Management? Contact Us Now!

How to Prevent Warehouse Management System Failure Before You Scale?

If you’re planning to grow, prevention is far cheaper than rescue. Here’s a practical checklist to avoid major WMS deployment challenges.

What to Audit in Your Current WMS?

- Peak order per hour capacity.

- Concurrent user limits.

- Sync latency with ERP.

- Inventory write conflicts.

- Report query load.

Most causes of warehouse management systems to fail appear only under stress.

How to Validate WMS + ERP Integration?

- Test API rate limits.

- Simulate retry storms.

- Validate duplicate prevention.

- Monitor sync lag.

How Do We Design Scalable Warehouse Management Systems?

We don’t build warehouse systems just to “work.” We design them to scale safely. Here’s the WMS approach:

- Scale-first warehouse management system architecture.

- Deep workflow mapping before build.

- ERP + WMS integration frameworks.

- Real-time event pipelines.

- High-volume transaction design.

- Peak load simulation before go-live.

We’ve seen repeated warehouse management system failures across industries, and we design specifically to avoid those failure points.

How Can We Help You Fix or Rebuild Your Warehouse Management System?

If your system is already showing strain, you don’t always need a full replacement. Sometimes you need a scalability redesign. We can help with:

- WMS scalability audit.

- Performance bottleneck analysis.

- Integration failure diagnosis.

- Architecture redesign.

- Safe migration to a scalable warehouse management system.

We work with your ops + tech teams together, because warehouse software problems are never just technical, they are operational.

What Smart Logistics Teams Do Before Scaling Their Warehouse Systems?

A warehouse management system should not just support today’s operations; it should survive tomorrow’s growth.

Most warehouse management system failures are predictable:

- Weak architecture.

- Poor integrations.

- No scale testing.

- Shortcut implementations.

If you’re planning growth, adding warehouses, or seeing early warehouse software problems at scale, now is the right time to act.

FAQs

- Slow performance, inventory mismatch, ERP sync delays, and peak load crashes are the most common failures.

- Because they were not architected for high concurrency, multi-warehouse operations, and real-time integrations.

- Warning signs include dashboard lag, delayed pick lists, stock mismatches, and integration backlogs.

- Yes. ERP sync delays and API failures often lead to wrong dispatch and billing errors.